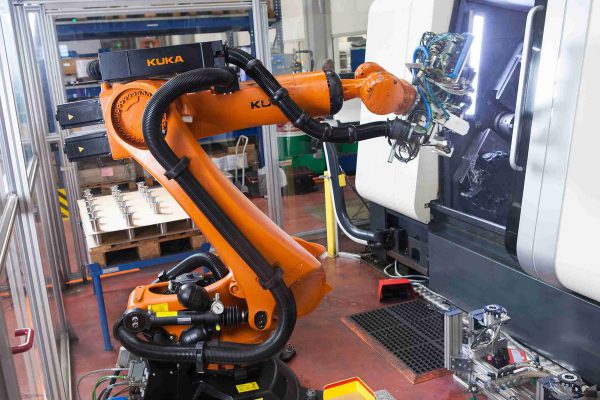

Total costs and benefits of implementing Industrial Robotic Arm

Robot is used in industrial production. Industrial robots are automatic, programmable and capable of moving on two or more axes.

In manufacturing Robots can repeat a job with high precision and manipulation. As a result, manufacturers can improve the output, quality and uniformity of products.

Of course, besides the high efficiency that robots bring, the cost to own them is not cheap. Enterprises need to consider their needs and carefully analyze the accompanying costs, including investment costs for procurement, installation and maintenance of robots.

Along with that is the cost of integrating the robot with other machines, equipment, programs or peripherals (gripper or sensor, robot arm controller) as well as the cost of upgrading the system to ensure safe. In addition, businesses should thoroughly understand all components of an industrial robot arm.

1. Overview of the most popular industrial robots today.

Before embarking on building or upgrading your business with an industrial robot product, you need to know what type of business your business is in and what is the name of the robot to use?

7 Types of Industrial Robots (Classified by Name) that you need to know

- Robot Palletizing – Bốc xếp hàng hóa

- . Robot Arc Welding – Hàn gia công cơ khí

- Robot Pick and Place – Gắp và sắp xếp sản phẩm

- Robot Foundry and Forging – Đúc và rèn

- Robot Milling – Robot Phay

- Robot Waterjet Cutting – Cắt bằng tia nước

- Robot đánh bóng

See details of today’s popular industrial robots:

https://limisys.vn/cac-loai-robot-cong-nghiep/

2. 7 Benefits of applying Industrial Robotic arm in production

2.1 Improve production efficiency and quality

Những cánh tay Robot đã được lập trình sẵn với các chức năng tương tự như cánh tay người. Cùng với khả năng linh hoạt cao, thiết bị này sẽ giúp bạn nâng cao hiệu quả và hiệu suất công việc mà không cần giám sát 24/24 như con người.

2.2 Space saving

Thanks to its flexibility and high applicability. Now, the same thing you don’t need to use a lot of human resources or heavy machinery anymore.

Just one industrial robot arm is more than capable of completing these tasks quickly and accurately

2.3 Cost savings

The ultimate goal of businesses is to optimize and how to minimize operating costs while ensuring high performance.

Then the industrial robot arm is the most accurate solution for businesses in the current 4.0 era.

2.4 Limiting errors

The application of industrial automation robots can produce mass products, with higher uniformity and quality, because machines always operate with accuracy, continuous repetition, no loss phenomena. concentration, boredom, fatigue, attitude… like using human labor.

2.5 Occupational safety

The current industrial robot arms are always equipped with sensors to detect impact forces and obstacles in the operating area, ensuring the devices will not cause harm to people.

Using Robots reduces the risk of occupational accidents, making it easier for businesses to comply with occupational safety rules or standards.

2.6 Saving raw materials and reducing product costs

The application of robots in production helps to reduce defective and damaged products. The production stages always ensure accuracy and standards, so the waste of raw materials and spillage is greatly limited. Increasing production and reducing waste will naturally lower product costs.

2.7 Enhance brand reputation, increase business competitiveness

The application of automation robots with a series of benefits mentioned above will help businesses meet exactly the progress and product quality required by customers.

The production operation process minimizes errors, thereby helping businesses improve brand reputation and increase competitiveness.

In Vietnam, LIMISYS is one of the TOP 3 companies that receive construction solutions related to Industrial Robot Arms in general and Fanuc Robot Arms in particular. For more information, please contact: 0982804347

3. How much does the industrial robot arm cost to invest in production?

Normally, the cost to invest in a production line that is fully equipped with both the operating system as well as the accompanying robotic arms depends on the technology and the field in which the business unit operates.

If it is just a small production line, the installation cost is only a few hundred thousand dollars, if it is a high-tech line, the installation cost can be millions or tens of millions of dollars.

The problem of balancing costs and benefits

However, the benefits of deploying an industrial robot arm in a production line will certainly far outweigh the costs that businesses have to spend every month and year, specifically:

-

For manufacturing industrial enterprises, the biggest cost to maintain the operation of the factory lies in the cost of wages and salaries. This cost in large enterprises will be tens, even hundreds of thousands of dollars per quarter. However, when deploying an industrial robot arm in a production line, this cost will be virtually eliminated.

-

In addition, in terms of cost, if viewed from a short-term perspective, robot deployment will not be suitable for your business, but if you look at it in the long-term, this is an optimal and least expensive solution.

To receive detailed information as well as PRICE of Industrial Robot, please contact us.

LIMISYS – CTY TNHH CƠ ĐIỆN TỬ LIÊN MINH

Địa chỉ: 128, Lê Văn Thịnh, KP6, P. Bình Trưng Tây, Thành phố Thủ Đức, Thành phố Hồ Chí Minh, Việt Nam.

Website: https://limisys.vn/

Email: info@limisys.vn

Fanpage: https://www.facebook.com/LIMISYSVN/

Hotline: 0982804347 hoặc 028 3743 7768

4. Chẩn đoán tình trạng sức khỏe máy CNC MIỄN PHÍ

Currently, LIMISYS is providing a service of DIAGNOSTIC HEALTH STATUS of CNC cutting machines. ability to help detect problems and damage that may occur in a timely manner. Avoid time and performance exit failures during product manufacturing.

Register for the service at the link

: https://limisys.vn/sua-chua-may-cnc-mien-phi/

Limisys – Lien Minh Mechatronics Co., Ltd

Hotline: 0982804347 hoặc 028 3743 7768

128, Le Van Thinh, KP6, Binh Trung Tay Ward, Thu Duc City, Ho Chi Minh City, Vietnam.

Tiếng Việt

Tiếng Việt